Sentry Ultraviolet Light Systems Clean Up Chloramines in Public Swimming Pools

Kill Pathogens Such as Cryptosporidium and E-coli on Contact to Combat Increased Illness Outbreaks

Norcross, GA May 24, 2017 – A report this week from the Centers for Disease Control and Prevention (CDC) citing a two-fold increase in cryptosporidium, more simply known as “crypto,” outbreaks points to the need for Ultraviolet lights to enhance public swimming pool sanitization, according to Steve Pearce, Executive Group Vice President, ChlorKing®, manufacturer of Sentry UV systems and salt-based chlorination systems.

Cryptosporidium is a microscopic parasite that can make otherwise healthy adults and children feel incredibly sick with stomach cramps, nausea and bouts of diarrhea that can last up to three weeks. Its levels can be mitigated by treatment.

Cryptosporidium is a microscopic parasite that can make otherwise healthy adults and children feel incredibly sick with stomach cramps, nausea and bouts of diarrhea that can last up to three weeks. Its levels can be mitigated by treatment.

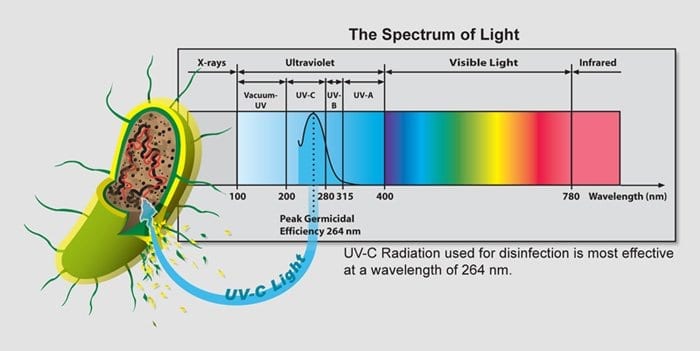

“UV lights are designed to destroy chloramines and other pathogens on contact with UV-C light,” Pearce said. “When used in combination with properly maintained chlorination systems, they can effectively keep bacteria in pools at safe levels – especially when swimmers follow good hygiene practices.”

UV systems are sized according to the flow (measured in gallons per minute) of a pool’s pumping system. They can be installed vertically or horizontally and will fit into most existing pump rooms. ChlorKing offers eight sizes with flow rates ranging from 50 to 1,600 GPM with available flange sizes from 2 to 8 output lamp technology. While UV is being produced at 254nm, ozone is also being produced at 185nm, adding to the sanitization of the water flowing through the chamber. This additional sanitizer helps reduce the amount of chlorine a pool or spa requires. All models operate at 120v with a maximum of 12amps, making them more cost-effective to operate and maintain. Lamps are rated for 13,000 hours (over twice as long as comparable medium-pressure systems).

“Our UV systems can be installed in a few hours, and they can begin improving water quality as soon as water flows past them,” Pearce said. “They also help the air in indoor pools once your ventilation system removes the noxious odors, which can cause respiratory problems.

In the United States, UV systems are considered a supplemental disinfection system, meaning they must be used in conjunction with chlorine or saline-based sanitization systems, such as ChlorKing’s Chlor SM salt chlorinators and NEX-GENpH on-site batch chlorine generators. Both systems eliminate the safety and cost issues associated with buying, storing and handling bulk chlorine, including the release of toxic chlorine gas when the chemical is mishandled. Salt-based sanitization systems eliminate the burning feeling in swimmers’ eyes and sticky feeling on skin and swimsuits.

“Today’s technology can do a fantastic job of keeping swimming pools safe and clean,” Pearce said, “but it can do a much better job when people follow the rules of good hygiene, as the CDC points out. They include showering before swimming to wash off contaminants and washing hands frequently, especially for parents who have just changed their children’s diapers.”

Learn more about Sentry UV systems, including sizes and installation.

About ChlorKing

Founded in South Africa in the 1970s, ChlorKing moved its manufacturing and distribution operations to Atlanta, Georgia in 1999. With more than 10,000 commercial swimming pool and water park installations worldwide, ChlorKing is the world’s leading designer and manufacturer of on-site chlorine generation and salt chlorination systems. The company’s patented technology produces large amounts of chlorine in a single cell, eliminating the need for banking multiple small cells. ChlorKing Inc., 6767 Peachtree Industrial Blvd., Norcross, GA 30092-3665. Tel: 770-452-0952 sales@chlorking.com www.chlorking.com.

Leave a Reply